Why Corrugated Metal Roofing & Siding Is the Best Metal for Your Pole Barn

July 27, 2021

Whether you’re looking to build a new pole barn or aim to renovate your existing barn, it’s crucial to know what types of materials you plan to use. The right materials can make a notable difference in the overall quality, structure and appearance of your pole barn.

One of the most reliable materials that you can use to build your barn is corrugated sheet metal. Corrugated metal roofing boosts the durability of the building and guards it against damage, helping contribute to a higher lifespan overall.

If you’re still on the fence about using this popular material, we’re here to give you the answers you’re looking for. Here’s everything you need to know about corrugated metal siding and why it’s the best type of metal for pole barns.

What Is a Pole Barn?

If you’re planning a construction or renovation project, you’ve likely come across the term “pole barn” at one point or another. A pole barn is a form of post-frame construction, which refers to a method used to build reliable, sturdy structures in a quick and efficient manner.

Buildings that are created through post-frame construction are highly adaptable and require fewer materials, which can help builders save money in the long run. Pole barns in particular are framed by posts, which serve as an inexpensive yet reliable foundation. Posts are also less time-consuming to prepare than other materials.

Installing a pole barn offers a wide range of benefits. One of the biggest advantages is a lower cost. There is far less foundation work involved in the construction of a pole barn, which means you don’t need as many materials to get the job done. Likewise, you can save a lot of time by opting for a pole barn over a traditional one.

Moreover, many people are enticed by the good insulation promised by pole barns. Because there is so much space between each post in the barn frame, barn owners have the opportunity to enjoy better insulation all year long.

What Is Corrugated Sheet Metal?

There are numerous types of materials that you can use to construct your barn. However, most builders are in agreement that corrugated sheet metal is the optimal choice for a pole barn.

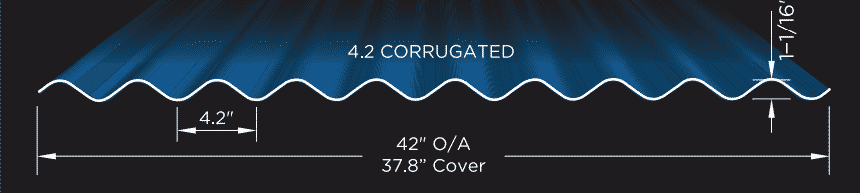

Corrugated metal is produced using a cold-form process. This means that each sheet of metal is pressed flat before going through a roll former. During the roll forming process, corrugations are added to the sheets of metal, and each sheet is cut to a specific length.

The end result is corrugated sheet metal that can be used for a wide variety of purposes. If you’ve decided to use corrugated metal roofing or siding for your barn construction project, you’re far from alone. Corrugated sheet metal is often seen as a long-term solution to various building needs, particularly for roofing and siding.

This material has become a widely popular choice over the years, and not just for barns. Homeowners have also come to rely on corrugated metal due to its many positive traits.

Benefits of Corrugated Metal Roofing

The benefits of corrugated metal roofing and siding are plentiful. As a result, this material continues to be one of the most trusted choices for builders of homes, pole barns and other types of structures.

Corrugated metal is best known for its strength and durability. This material is specifically designed to withstand various forms of damage, including the following:

- Rain

- Hail

- Harsh winds

- Water penetration

- Fire damage

Corrugated sheet metal is also adept at keeping pests at bay, which can prevent rotting. This is especially important if you house animals inside your pole barn and need to provide them with a safe, healthy living environment.

Moreover, corrugated metal siding is built to resist the impact of objects that collide with your barn. This material is approximately four times less likely to dent or warp than standard vinyl siding. If you’re dealing with hot weather in your area, metal siding is unlikely to expand, as well. This helps preserve the structural integrity of your pole barn.

If you’re looking to get the most use out of your building materials, corrugated sheet metal is your go-to option. This material requires minimal maintenance, allowing you to dedicate your time and energy to other pressing tasks. In addition, if you do your part in taking care of what little upkeep is needed, you can expect to have your corrugated metal roofing last for fifty years or more.

Uses for Corrugated Metal

Because corrugated sheet metal is such a versatile material, you can use it for many different purposes. If you use corrugated metal to build the roof of your pole barn, you’ll benefit from strong roofing that resists the elements while providing waterproof protection. Meanwhile, corrugated metal siding is highly resilient and helps guard against pests, water damage and other hazards.

No matter how you decide to put corrugated metal to use when constructing your barn, you’ll make your life significantly easier with help from this material. Be sure to speak to a professional if you aren’t sure which type of material is right for you or need guidance on how to incorporate it into your barn.

Getting the Most Out of Corrugated Sheet Metal

At Creative Building Supply Co., we offer a vast selection of corrugated metal sheets tailored to fit your unique needs. Our state-of-the-art metal fabrication shop can create metal panels in any type of material or gauge. Thanks to our wide array of popular styles, sizes, colors and finishes, you’ll have no trouble finding a material that aligns perfectly with your goals.

Whether you’re planning a corrugated metal roofing or siding project, this popular type of material can be adapted to almost any kind of construction needs. Your pole barn needs optimal care and high-quality products to last long and do its job right.

To learn more about the different types of materials we offer and how we can help bring your project to life, reach out to the experts at Creative Building Supply Co. today.