Learn More About Metal Fabrication for Car Restoration

July 15, 2021

Ask any car restoration enthusiast what their favorite part of the restoration process is and they’ll almost always say the bodywork. Depending on how badly a car’s body is dented, scratched and/or corroded, you might be able to apply acidic rust treatments, use car paint to cover scratches or pull out minor dents.

When panels, hoods and other car body parts are beyond fixable, you’ll need to get the best corrugated metal panels that will restore your car to mint condition.

What is Corrugated Sheet Metal?

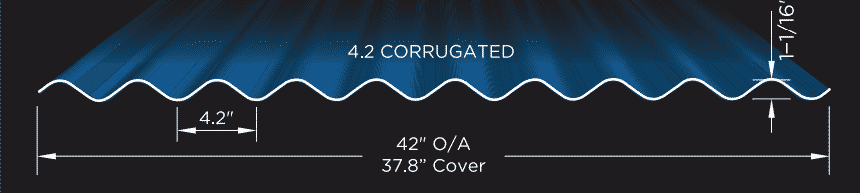

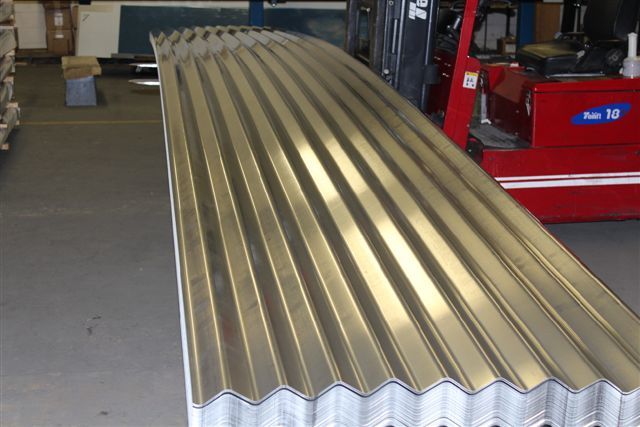

Corrugated sheet metal is a versatile, lightweight building material recognizable by its rippled, or corrugated pattern. Corrosion resistant and durable, corrugated sheet metal can be easily coated with a variety of colorful varnishes or paints. The versatility and workability of corrugated sheet metal makes it a popular choice for roofs, decks, sidings and for restoring automobiles

A corrugated metal panel customized to meet specific dimensions of your auto restoration project is made using a cold-form process. Panels are pressed and rolled to create a certain corrugated shape.

Since each corrugation formed in a metal panel enhances tensile strength, metal panels with multiple corrugations will provide even better resistance to impacts and weather damage. In addition, corrugated metal is one of the easiest types of metal panels you can manipulate and work with when restoring a car.

Galvanized Sheet Metal for Car Restoration Projects

Galvanized metal has been dipped in molten zinc to provide strong protection against corrosion. The small amount of iron in a metal panel reacts to zinc by forming an alloy that gives metal panels a glossy yet durable finish.

Another method for galvanizing corrugated metal panels called Galvalume has become a favorite galvanizing method among car restoration professionals. Consisting of silicon, aluminum and zinc, Galvalume coats sheet metal panels for maximum protection against oxidation.

Galvalume is also more resistant to liquids, such as water and gasoline, which accelerate oxidation. In fact, sheet metal coated with Galvalume may remain rust-free for as long as 10 to 15 years.

Types of Corrugated Sheet Metal for Car Restoration

Mild (Steel) Sheet Metal

Mild steel contains minimal carbon to help improve on pure iron qualities. In most low carbon steel materials, the amount of carbon contained in the steel ranges between .05% to .25%. Other elements can be incorporated in mild steel to enhance tensile strength, resistance to wear and tear and prevent corrosion.

Steel that is appropriately heat treated increases in carbon content. When deciding what kind of sheet metal to use for car restoration, be aware that the higher the carbon content in steel, the less hard and ductile it becomes.

Steel ductility refers to the ability of a piece of steel to bend when pressure is applied. So, for purposes of restoring automobiles, it is important to know that higher carbon steel will offer better hardness and strength.

A great choice for replacing door skins, firewalls or fenders, mild sheet metal strong, malleable and easy to weld. Mild steel is also cost-effective if you need to stick close to a budget.

Some mild steel panels may require anti-corrosive treatment before use. However, don’t use heat when treating a mild steel panel. Heat can interfere with carbon content and reduce the durability of mild steel.

Aluminum Sheet Metal

Advantages of aluminum sheet metal for car restoration include:

- Lightweight/easy to handle (this makes it a top choice for restoring dashboards)

- More resistant to corrosion than steel

- Can be anodized/painted in different colors

- Stronger than mild steel

- Recyclable

Although aluminum costs slightly more than mild steel, it is more affordable than brass or stainless steel. When welding aluminum, be aware that it tends to tear easily.

Car restoration experts recommend using only a TIG or spool gun MIG welder to avoid tearing aluminum sheet metal. Aluminum also works well for bulkhead restoration projects.

Stainless Steel Metal Panels

An alloy of chromium, nickel, iron and various metals, stainless steel is exceptionally resistant to corrosion and long-lasting. Due to its high melting point, stainless steel is an ideal material for tubing, panels, brackets and interior trim. The only disadvantage to using stainless steel for car restoration purposes is that it costs more than mild steel or aluminum and it will readily show dirt and smudges.

Vehicles made between the 1920s and the 1970s will almost always have stainless steel trim. When old car trim can’t be restored to its classic appearance, contact CBS Sheet Metal for information about customized stainless steel panels.

What to Know About Sheet Metal Gauge

When researching which type of metal panels would work best for your car restoration project, get to know something about gauge standards. Gauge is the thickness of a piece of sheet metal. In the past, automobile sheet metal once ran around the 18 gauge mark (approx. 0.047 inch).

Today, auto sheet metal commonly carries gauges of 22, 23 and 24 and is considered high strength steel. Measure sheet metal gauge by using a tape measure and multiplying millimeters by .03937 to come up with a measurement in inches.

Get Superior Customized Corrugated Sheet Metal Panels from CBS Sheet Metal

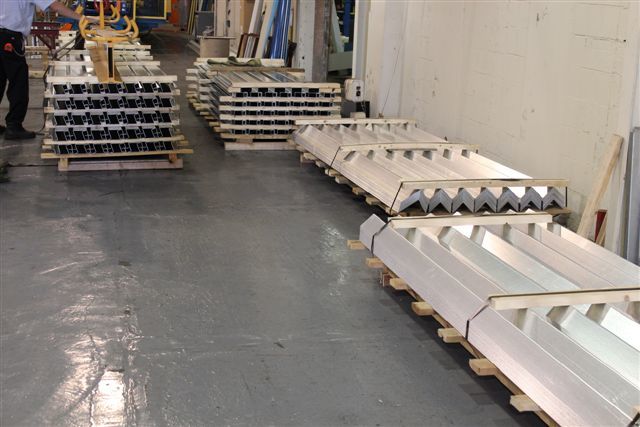

We understand the amount of time, money and hard work you put into any car restoration projects. That’s why when you purchase sheet metal for muscle, antique, classic or vintage car restoration from Creative Building Supply Co., you receive metal panels precisely meeting your specifications.

CBS Sheet Metal offers corrugated metal panels in various sizes, gauges and finishes that we guarantee will exceed your expectations. We also specialize in stainless steel, steel, aluminum and reinforced plastic fabrication to accommodate all your car restoration needs.

Check out our comprehensive inventory of corrugated sheet metal panels or don’t hesitate to call us to order customized sheet metal or to get help with determining what kind of sheet metal would work best for your car restoration project.