2021 Steel Pricing Update & Metal Roofing Cost Guide

August 24, 2021

Metal roofs are long-lasting and durable. The upfront cost is offset by their minimal maintenance and ability to outlast traditional asphalt shingles. As prices drop in the second half of 2021, you may want to consider getting a metal roof installed.

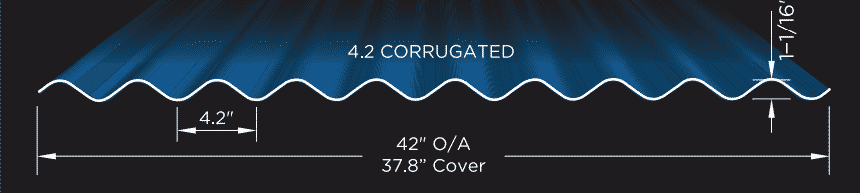

What Is Corrugated Metal Roofing?

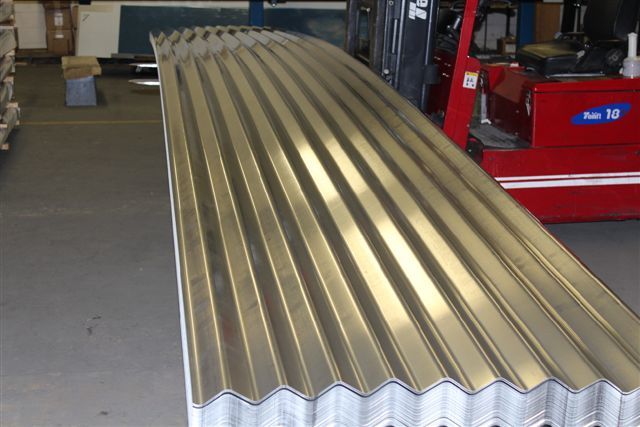

Metal roofing refers to pre-cut panels of sheet metal that are fasted together using rivets and screws. This type of roofing material comes in a variety of colors, shapes, and finishes. The most popular look is ribbed or waved, but you can select an option that appeals to you and works best for your needs. The finish that you choose is important since this is responsible for keeping the metal in good condition and offering protection from the weather.

- Galvalume is composed of aluminum and zinc and resists corrosion. This finish is very long-lasting

- Galvanized is a zinc barrier that prevents corrosion. It’s one of the most popular choices

- Painted finishes protect the metal from the elements and retain its color well

- Stainless Steel is an excellent choice to resist corrosion. A number of finishes are available to achieve a look from mirror gloss to brushed.

Each type of finish has its benefits. Which one you should choose depends on your needs and purposes.

Are There Benefits To Metal Roofs?

The many benefits of metal roofing make them a worthy alternative to asphalt shingles. They are fire-resistant and also insect and pest-resistant, as well as environmentally friendly. Many metal roofing materials are manufactured using recycled materials.

One of the most appealing benefits of a metal roof is its longevity. Roofs can be expensive to have installed. When you select a material that lasts, you won’t need to expend that cost very often. Regular shingles may last around 30 years when properly installed and cared for, while some types of metal roofs can last up to 100 years!

The aesthetic of metal roofing materials is appealing as well. You can have the metal panels painted in a wide array of colors. Once you have decided on a finish and look that you like, you can be assured that your new metal roof will retain its appearance well, with little to no corrosion or denting. The extent of its durability depends upon which material and finish you choose for your roof.

Yet another upside to having a metal roof installed is the savings you will experience in energy costs. Metal roofing is highly energy-efficient. Instead of absorbing heat from the sun’s rays, it will reflect it back in the direction it came. The surface of metal roofs is much cooler than most shingles and keeps your home itself cooler. You can save up to 40% on your energy costs with a metal roof.

How Do You Maintain a Metal Roof?

Metal roofs require little in the way of maintenance. Once installed, they don’t require any extensive upkeep. It’s a good idea to have a professional do a thorough inspection every few years, but normally you just need to check them for damage and keep them clean of dirt and debris.

Look for any loose panels, missing rivets, rust spots, and dents. These may need some repairs before greater damage is caused. If you notice any branches or other materials touching the roof, they should be cut back or removed. As long as you clean and examine your roof regularly, you should have no major problems.

What Is the Cost?

Metal roofing costs have been steadily rising during 2020 and the first half of 2021. Thankfully, there is some good news in the steel price updates lately. Costs have come back down significantly in the second half of 2021, making metal roofs more affordable.

The total cost of your new roof is found by factoring in several different variables. The price of your chosen material is, of course, a big part of the final cost. You also need to consider the size of the project, accessibility and complexity, as well as labor costs.

Another consideration that will affect the price is if the building already has an existing roof. A metal roof can usually be installed over top of an old roof, but two layers of roofing materials are the maximum recommended. Your roof also needs the proper insulation, framing, and decking.

Steel and other types of metal require a greater initial investment but it is well worth it. The durability of metal roofs means they can significantly outlast traditional shingle roofs by decades. You will actually be saving money when you consider how infrequently you will need to replace your roof.

Steel especially is much harder and heavier than most materials, making it a great choice if your home or other building structure takes a beating from regular storms or falling debris. Where a lighter metal like aluminum may dent from a fallen tree branch, steel can withstand a lot of impact without showing any signs of damage.

There are a whole host of benefits that come with a metal roof. It is a solid option that deserves greater exploration. You can customize your new roof in a variety of ways to make a statement or focus on functionality. Talk with a knowledgeable expert to get recommendations and specifications for your own needs.

What Next?

If you’ve got a job that will require corrugated metal roofing, call us today. We’ll run through the materials you’ll need and the best way to bring them to you. We are located in New Jersey so if you are a close neighbor in New York City, or Pennsylvania you can pick up, if not we ship worldwide at great rates!

You can reach our team of experts at 732.367.6333, or fill out our contact form so we can learn more about your needs.