Metal Decking For Concrete: How to Choose What’s Best For You

January 13, 2022

Composite floor decking made from corrugated metal panels have higher strength than flat steel floors. Find out how to choose the best corrugated metal decking for your construction.

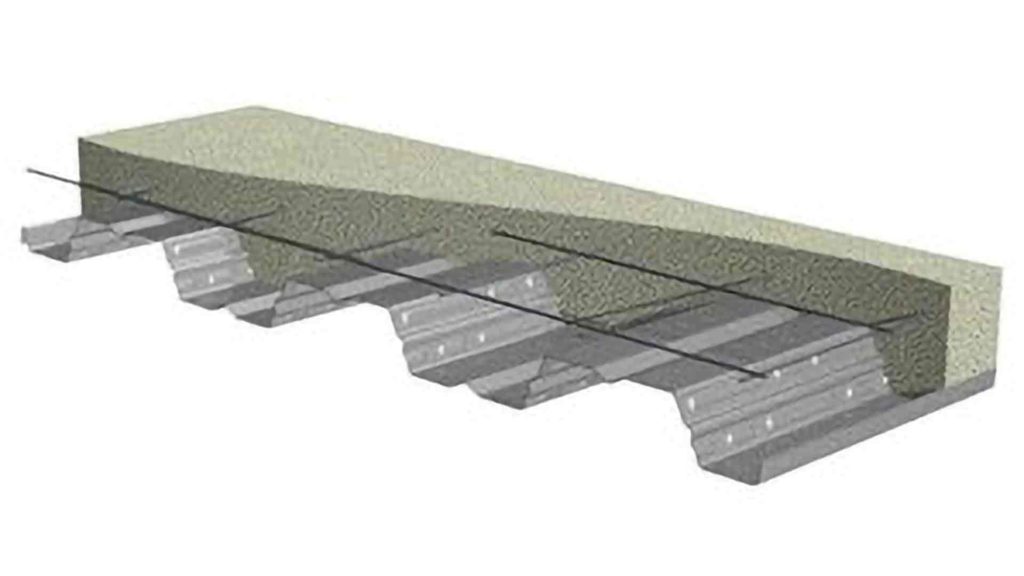

One way to strengthen your floors without adding any extra weight is bonding a corrugated metal sheet with concrete. The phenomenon is known as Sheet decking or composite floor decking. It optimizes the structural integrity of your construction.

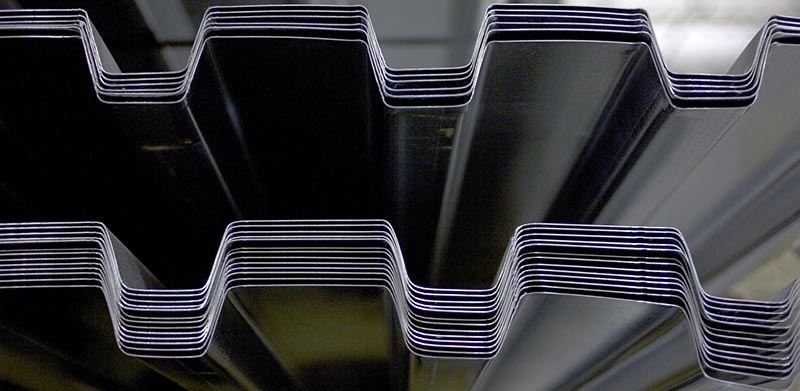

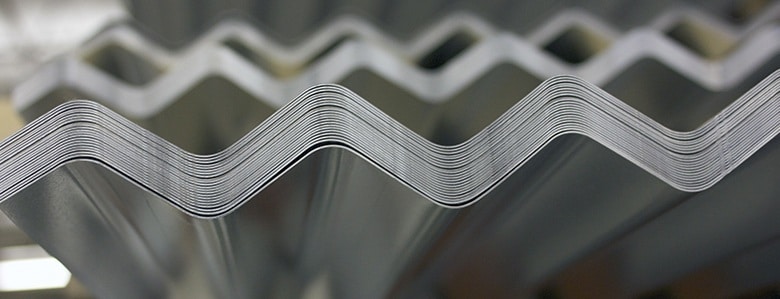

Today you can use different types of metals to strengthen the floor. However, corrugated metal sheets provide maximum strength. The metal sheet bends increase the surface area for bonding with concrete. Therefore, the resulting composite floor slab has higher strength unlike, plain concrete slabs or plain metal decking.

Advantages of Using Composite Slabs

Slabs reinforced with corrugated metal decking have stability and are low weight. The reduction in mass decreases the number of support for slab casting. Thus, you end up saving on construction material.

Furthermore, composite slabs cut costs by downsizing the amount of concrete required for slab development. Reinforcement from the corrugated steel sheet decreases the amount of concrete while maintaining stability. The feature makes steel form excellent for multistoried buildings.

You can purchase pre-made composite floor slabs by examining the building specifications indicated by the site engineer. Pre-made slabs are easy to set up and simplify the installation of shuttering materials. The slabs also have the allocation for setting cable trays and pipes that you can lay out once the slab is in place.

Features of the Corrugated Metal

At CBS Sheetmetal, Creative Building Supply, you can purchase quality composite slabs that contain top-notch corrugated metal. We manufacture our corrugated metal panels in-house. Aside from our standard metal line, we also customize metal panels to fit your engineering specifications.

We stock high-performance steel sheets with four types of finishes to prevent corrosion and fortify the strength of the corrugated metal.

The processes include:

- Galvalume – we coat the metal sheet with aluminum, silicon, and zinc for long-term protection against rust.

- Galvanization – is zinc overlay on the metal surface to buffer against oxidative elements.

- Painting – our metal sheets come in colored finishes for aesthetics and prevention against rust.

- Stainless steel – the metal alloy is resistant to rust and does not require additional finishes.

There are various steel forms suitable for different applications in construction. Every metal decking has unique features that meet specific building requirements. You can compare and contrast our list of corrugated metal decking to see what works well with your construction needs.

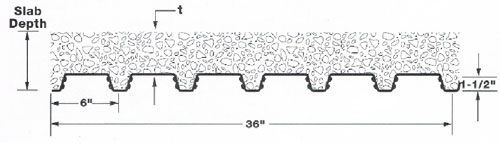

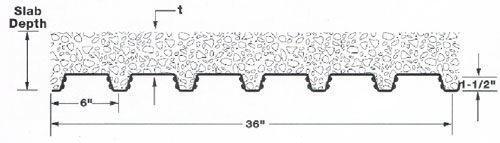

B/Type B Composite Floor Decking

The B/Type B steel floor is the most common type of metal decking for concrete. It is suitable for short- and medium construction spans.

Features Include:

- The measurement from the trough to the peak is 1.5 inches.

- It has a 36-inch width.

- The distance between adjusted trenches is 6 inches.

- It has six wide ribs.

- It has the standard male-female interlocking side lap.

Our corrugated sheet has two additional ridges on either side of the trough slope. We join the corrugated metal sheet with lightweight concrete with 115 PCF or a 145F normal-weight concrete.

Our corrugated sheets have an equal distribution of elements per foot of width, distributing equal weight and mass throughout the surface.

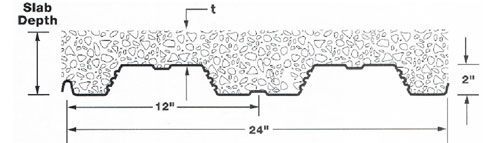

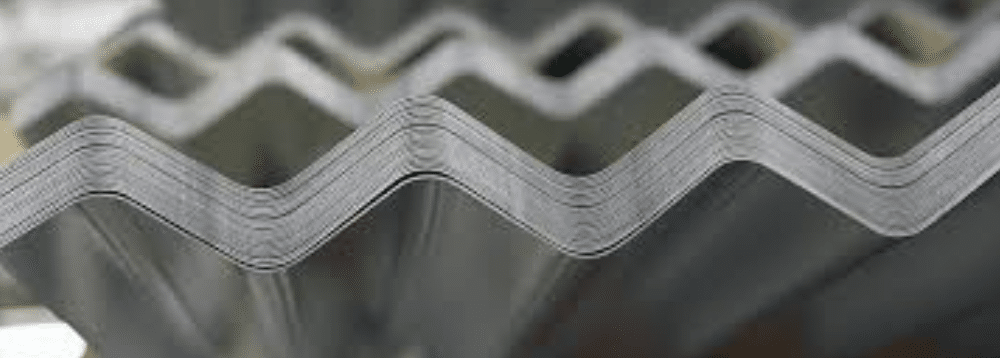

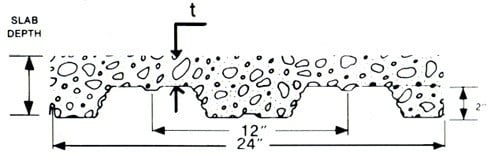

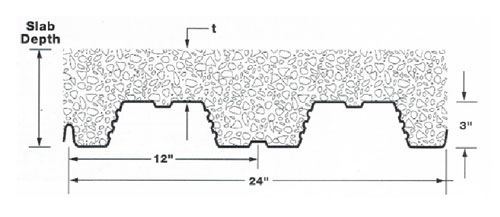

Two-Inch Composite Floor Deck

The two-inch composite floor deck is stronger than the type B steel floor. The corrugated iron sheet can handle more concrete weight in contrast to the B metal sheet. The slab also spans further distances.

Features Include:

- The measurement between the peak and trough of the metal sheet is 2 inches long.

- The metal panel is 24 inches wide.

- The distance between two mid-troughs is 12 inches.

- It has two wide ribs.

- It has the standard male-female interlocking side lap.

We fill the slab with a 115 PCF lightweight concrete or normal-weight concrete with a 145 PCF.

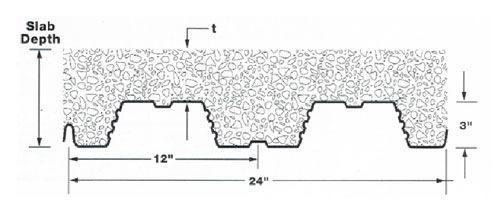

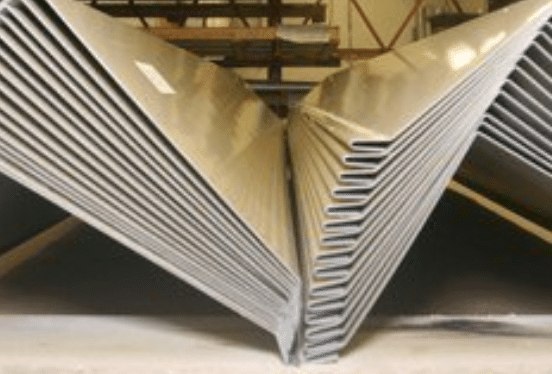

Three-Inch Composite Floor Deck

The three-inch metal panel is superior in strength and depth compared to the 1.5-inch and the 2-inch sheets. It can also span the most distance between supports. The metal panel also holds the thickest amount of concrete.

Features Include:

- The length between the trough and peaks of bends is three inches.

- The sheet panel is 24 inches.

- The mid-trough width is 12 inches.

- The arches have additional curvature on the slopes and base for maximum surface area.

We fill the metal sheet with 115 PCF lightweight concrete or the 145PCF, the norma-weight.

Specialized Composite Floor Decking

There are ways of making long-span floor composites. The 1.5, two, and three-inch metal decking slabs are the most common. However, they span limited distances. You need to purchase steel forms beyond three inches for slabs covering long distances.

Using Steel Joints

You can create long-span composite slabs by joining composite steel joists with steel floors using shear studs connected to the steel decking to the joist top chord. When you pour concrete on this integration, the shear studs get embedded on the cured concrete, creating one long composite system. The integration provides slabs that span 20 to 60 feet.

Deep Ribbed Composite Deck

In this floor composite system, 4.5, six, or seven-inches metal decking are joined together on the side using a fastening tool. The connection takes place on-site. The steel floors cover up to 34 feet.

Dovetail Composite Deck

The dovetail composite deck can span up to 34 feet. It is suitable for mid-rise private houses and hotels and is available in 2 inches and 3.5 inches. The steel decking system provides thinner floors that increase ceiling height for multistoried buildings.

Contact Us

Creative Building Supply is a hub for metal decking for concrete and has over 20 years of experience and expertise in metal decking. Our fabrication shop enables us to make an array of metal panels for walls, floors, and roofs. We also provide custom roll-making to give you a unique design for your metal panels.

We ensure you get quality steel floors with our signature metal panels made in-house. The high load-bearing floors will serve your building well because of their strength and lightweight characteristics. Our metal decking stands the test of time. If you are looking to purchase a composite floor decking, call us at (732)367-6333 or fill out our contact form so we can learn more about your needs.