Galvanized Steel vs. Stainless Steel – CBS Sheet Metal

Posted September 14, 2021 by CreativeBuildingSupply

For over four thousand years, steel has brought strength, function and beauty to architecture, transportation and artistic projects. Arguably, steel is the most important construction material around the world. Whether you’re planning on a big-budget build or a simple decor update, steel provides a plethora of options. Should you go with stainless steel or galvanized? What’s the difference between Galvanized Steel and Stainless Steel?

Steel Basics

Put simply, steel is an alloy — a mix of iron and carbon with minute percentages of other elements. To manufacture basic steel, foundries heat iron ore and a special type of coal using extreme temperatures. The process is lengthy and removes impurities, ensuring the strength is intact for the final product.

Depending on which elements are added or left in the steel, a grade is assigned. Grading allows architects and engineers to choose the correct strength and quality for their projects. Further along in the manufacturing process, a gauge is chosen depending on how the steel will be used. Gauge is the thickness of the steel once rolled out. The higher the gauge number, the thinner the steel.

How Stainless Steel Is Made

During the manufacturing process, chromium, nickel and other elements are added to the mix to create stainless steel. The addition and exact percentages of these elements provide excellent corrosion protection and durability. The molten steel is then poured into shapes, rolled, heated and cut into usable forms, such as stainless steel sheet metal.

How Galvanized Steel Is Made

To make galvanized steel, ordinary steel is dipped into molten zinc. Over time, the zinc coating begins to corrode, giving the galvanized steel a protective coat. This method gives galvanized materials a unique, mottled finish along with added strength and durability for a wide range of applications.

Stainless Steel vs. Galvanized Steel

Deciding which material to use in your project requires understanding the differences and benefits of stainless steel versus galvanized steel.

Durability: Stainless steel is mechanically stronger than galvanized steel, as the alloy elements are “built in” to the steel, whereas galvanized steel has only been coated with zinc. The zinc does give the galvanized steel a rust-resistant coating. The coating also extends the life of “plain steel” by several decades, depending on water exposure. Stainless steel, on the other hand, will not rust. It’s heavier and can be used in more rugged construction applications.

Environments: Galvanized steel will hold up well in most environments — unless there’s saltwater involved. If the galvanized coating becomes nicked or compromised, the saltwater will eventually lead to rusting issues, though the zinc coating is highly durable and rust-resistant. Stainless steel can withstand all types of outdoor elements, including marine environments.

Price: Galvanized steel is less expensive than stainless and typically used in lower-budget projects as it’s more malleable and easier to work with. Stainless steel manufacturing is a more involved process, driving up the cost. Stainless is also heavier and requires more labor to fabricate.

Surfaces: Stainless steel typically has a shiny sheen. Galvanized steel has a more mottled, dull gray pattern that will oxidize with a white coating. As stated above, stainless steel will not rust; galvanized steel may rust if the durable outer coating is damaged.

Additionally, many fabricators can add color to the manufacturing process, giving multiple design options, including matte and metallic finishes. In addition to aesthetics, coloring steel of either type can add another layer of protection against the environment, add an element of safety, and camouflage into natural surroundings.

Applications for Stainless & Galvanized Steel

Kitchen sinks are top-of-mind for some people when thinking about stainless steel applications, and grandma’s water bucket may come to mind when thinking of galvanized steel. However, the applications for these durable steels reach far beyond these everyday uses.

When choosing which type of steel to use in your project, it’s important to take the above-mentioned categories of durability and cost into consideration. The type of finish you’re after will also determine which material is best suited for your needs. Do you want shiny, uniform, and sleek? Stainless steel will be your go-to. Do you want matted and modeled? Galvanized will be your best bet.

Additionally, seeing how others have used steel for the best outcomes may help you determine how to move forward with a construction job, remodel, or other creative endeavors.

Best Uses for Stainless Steel

For everyday use, stainless steel can be safely sterilized for use in dental and medical devices, kitchenware, and home and industrial appliances.

For interior design, appliances, backsplashes, door handles, and handrails are frequently constructed from stainless steel. Adding stainless steel elements to a remodel or construction project also increases the real and perceived value, as many consumers seek out this higher-end finish.

Stainless steel’s strength and durability make it ideal for applications in heavier construction projects like skyscrapers and bridges. ars, railways, airplanes, and many other high-end products. Though more expensive than galvanized options, some people do opt for stainless steel roofing and siding solutions.

Best Uses for Galvanized Steel

Galvanized steel is a popular option for lower-budget projects. Some common uses for galvanized steel are ductwork, fasteners like nails, screws, and bolts, metal cabinetry, and railings. Street signs, ramps, and gutters are also popular applications.

Because of its spangled finish and pliability, galvanized steel is also used in many decor elements like flower vases, containers, wall art, sculptures, and frames.

Galvanized metal roofing and siding panels are also popular options, as the zinc coating will last for decades.

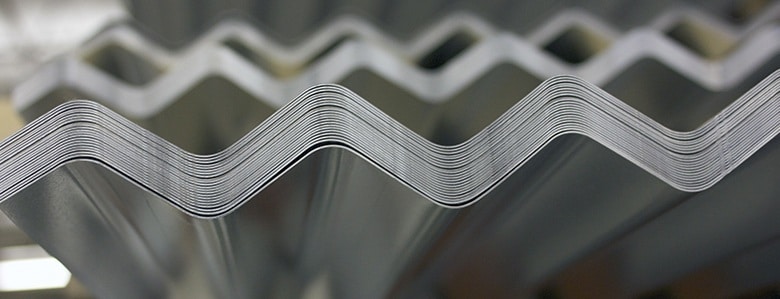

A common form for either steel is corrugated sheets. Corrugated steel sheets can be customized by a fabrication shop for roofing, siding, floor decks, gutters, and more. Depending on your project, you’ll need to consider finish options and gauge (remember, the higher the gauge, the thinner the steel thickness), and price.

To discover more about galvanized and stainless steel options for your projects, contact our skilled fabrication team today.

1 Comments

I appreciate, cause I found exactly what I was looking for. You have ended my four day long hunt! God Bless you man. Have a great day. Bye

Leave a comment